The chronicle from 1850 to today

MEILLER Kipper is celebrating 175 years. Join us on a journey of discovery from the establishment of our company in 1850 until today.

MEILLER Kipper is celebrating 175 years. Join us on a journey of discovery from the establishment of our company in 1850 until today.

Lorenz Meiller, the founder of the company, purchased a property on Lilienstrasse in 1850. It is here that the story of the Meiller enterprise began in Munich 175 years ago. The original premises on Lilienstrasse, where everything began, is still owned by the family today.

Franz Xaver Meiller, the nephew of Lorenz Meiller, took over the hammer mill and armoury in the Munich district of Au in 1881. Franz Xaver Meiller acquired the nearby workshop in Ottenhofen near Markt Schwaben, Upper Bavaria, in 1888 and transformed it into a hammer mill over the years.

The MEILLER company began with the production of tipping vehicles in 1907, thus laying the foundation stone for the “MEILLER tipper”. The tipping vehicles were originally operated manually using a gear winch, as hydraulic technology at this time was not mature enough for such operations.

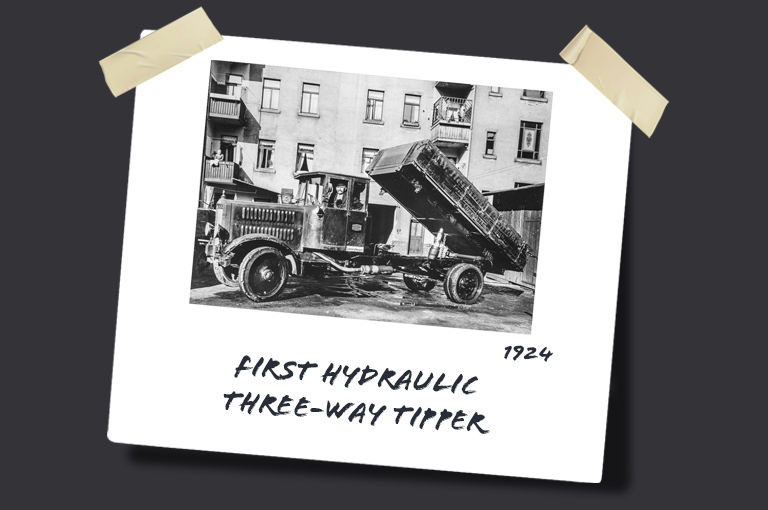

Pioneering technology: The first hydraulic three-way tipper, which attained the designation “MEILLER Kipper” D.R.P. (an imperial German patent) and other international patents, was launched on the market in 1924. A technical innovation that replaced the toothed rack winch, decisively altering the construction industry and paving the way towards modern tipping technology.

Innovation from Munich meets inspiration from the USA. MEILLER began production of the skip loader in 1953; a solution developed on Landshuter Allee. This was a milestone that revolutionised working with interchangeable trailers and permanently transformed the construction sector.

A thrilling look back at the beginnings of bauma, the largest international exhibition for construction machinery, building material machinery, mining machines, construction vehicles and construction equipment.

The exhibition made its début in 1954 with 58 exhibitors, 8,000 trade visitors and 12,000 square metres of open-air area on the Munich Theresienhoehe.

MEILLER showcased itself back then on a broad scale with a mobile Messeturm (Trade Show Tower), and this was also used at IAA in Frankfurt. One of our product highlights was our legendary rear tipper.

MEILLER commenced production of steel rear tippers in 1959 especially developed for export overseas. This robust tipper was developed for the efficient transportation of bulk materials up to a medium grit size. With a tipper body manufactured completely with steel, a flexible top-hinged tailgate and the option to extend the front panel as a protective roof, it provided absolute versatility and had a high degree of resilience.

1971 saw MEILLER accept the challenge to develop a revolutionary roll-off system that enabled the depositing of entire loading platforms, thus preparing the way for the hooklift! Ultimately, it proved possible to purchase the KUKA patent and optimise it for Germany. The first MEILLER hooklift was launched in 1972, this being completely hydraulic and dispensing with a cable.

1973 saw MEILLER setting new standards with the hydraulic Bordmatic. As steel replaced wooden side walls, opening and closing became a challenge - a challenge that was solved by a system without a cable hoist, but with a mechanical locking system and integrated hydraulics in the corner posts.

This was a real plus in terms of safety and efficiency. Aluminium side panels were also available on request. This technology still impresses today.

The Soviet Union commenced building the Baikal–Amur Mainline (BAM) in 1974 – a 3,200 km long railway line traversing the ice-cold expanses of Siberia. The demands made of the fleet were extreme, with temperatures up to -50 °C, impassable terrain and loads weighing tonnes.

Magirus trucks with MEILLER heavy-duty dumpers were used for this purpose. 9,500 vehicles, 8,000 of which had MEILLER superstructures, mastered these conditions, thanks to air-cooled Deutz diesel engines and sturdy, heated tipper bodies.The MEILLER hydraulics operated without problems in cold temperatures reminiscent of the Arctic.

A chapter of technological history that can still be felt today, as some of these vehicles are still in use.

The capacities of the MEILLER plant on Landshuter Allee in Munich were no longer adequate in the 1980s. 1984 therefore saw a move to the newly erected location on Untermenzinger Strasse in Moosach, Munich.

The relocation was realised in stages over more than a decade, being only fully completed in 1995. This ended the era of production on Landshuter Allee. The principal place of business today is still in Moosach, Munich.

MEILLER had already begun to erect its own branch in Karlsruhe in 1966.

An important step followed on 1 January 1990 with the takeover of the Adolf Spoth company which produced steel and construction machinery. The reason was the growing demand of the Daimler plant in Wörth for painted tipping superstructures with just-in-time delivery.

A modern assembly and painting facility was erected on the Spoth site. The location still operates under the name F. X. MEILLER GmbH & Co KG Fahrzeugbau Karlsruhe.

Due to the high demand on capacity, MEILLER began to look for another location for its production at the beginning of the 1990s. 1993 saw Slaný, around 30 km to the north-west of Prague, being selected for this purpose.

MEILLER acquired a site with an area of 90,000 m² and an existing building complex. Production commenced at the end of 1994, and 120 employees were already in action in 1995. A decision was reached only one year later that saw all steel construction, including tipper bodies and subframes, being moved to Slaný.

This saw work commencing on a central production location, and it still plays a key role in the MEILLER Group today.

MEILLER France was founded in September 1998 in Lipsheim, near Strasbourg.

MEILLER France quickly won over the market with customised products such as the Bibenne (two-way tipper).

Today, we not only serve customers in France and the Benelux countries, but also customers in French-speaking export markets such as New Caledonia and the overseas departments.

Acquisition of IFE Fahrzeugtechnik by MEILLER led to the creation of the Austrian subsidiary in 1999 located in Waidhofen an der Ybbs.

IFE was already installing MEILLER hydraulics and producing under licence, an ideal basis for entering the market.

Simultaneously, MAN relocated its truck production to Steyr, only 35 km away. MEILLER seized the opportunity to establish itself as a regional partner and supplier.

The launch of this project proved extremely successful, with products it developed itself such as the rock tipper.

The groundbreaking ceremony for the MEILLER plant in Niepołomice, only 20 km to the east of Kraków, was held on 14 June 2007.

A modern mounting and service location was created on the 24,000 m² site for three-way tippers, rear tippers, skip loaders and hooklifts. Production commenced early in 2008, with Poland and markets in Eastern Europe and the Baltic region being supplied.

MEILLER Polska is today an important player in the international manufacturing network.

The opening of a modern production location in Turkey by MEILLER in partnership with Doğuş Otomotiv saw the establishment of a joint venture in 2008. The plant is in Sakarya, an industrial city in the Turkish region of Marmara with a population of 300,000. It is therefore in a central location between Istanbul and Ankara.

Since then, tipping superstructures have been manufactured directly on location, a decisive step which addresses the needs of the Turkish market in an optimum manner.

The establishment and opening of this plant marked the beginning of a close cooperation uniting German engineering tradition with regional competence, firmly anchoring MEILLER in the Turkish market.

In 2008 MEILLER established the MEILLER Iberia S.L. subsidiary in Spain.

This step saw us create a direct contact point for our customers on the Iberian peninsula, closely integrated in the market, customer-focused and extremely reliable.

The location enables us to supply the Spanish market with our tipper solutions and services in an optimum fashion and, since it opened, strengthens our position in Southern Europe on a sustainable level.

With the introduction of the i.s.a.r.-control in 2010, MEILLER launched a pioneering innovation on the market, namely the world’s first radio-controlled remote control system for tippers.

The new control system combined the latest technology with practice-oriented operation – compact, robust and particularly user-friendly. This meant that our customers enjoyed greater safety, more convenience and considerably greater progress during daily work.

The introduction of the i.s.a.r.-control therefore marked a technological milestone that made our tipper solutions even more efficient and future-oriented.

MEILLER unveiled the RS21 hooklift in 2016, a completely new generation that set standards in terms of technology and reliability.

The RS21 impressed through its rugged construction, high degree of resilience and a practice-oriented design that made daily transport operations considerably more efficient.

This innovation combined proven MEILLER quality with the latest safety and productivity requirements.

The introduction of the RS21 therefore marked an important milestone in the further development of our hooklift series.

MEILLER Schweiz AG was established by MEILLER in 2017, taking another important step in its internationalisation.

The new location ensured the supply of spare parts directly on site, considerably shortening delivery times and improving the reliability of support for our customers in Switzerland.

MEILLER also expanded its international presence in 2017 through the takeover of Boweld Truck Bodies in Holywell, Wales.

This step saw MEILLER laying the cornerstone for a successful market launch in the United Kingdom. Boweld contributes many years of experience in the construction of tipping superstructures, perfectly complementing the product portfolio.

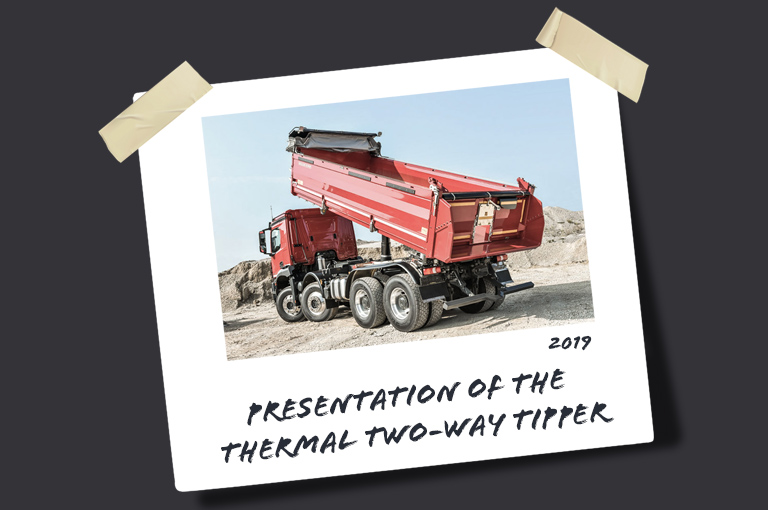

The thermally insulated two-way tipper (ZSK-ti) from MEILLER has impressed everyone as a real all-round asset since 2019.

Whether transporting sand, gravel, crushed stone or excavated material, its powerful hydraulics, stable side panels and the optional remote control system make it ideal for tipping any load to the left or the rear, rapidly, safely and precisely.

The ZSK-ti therefore represents a maximum degree of functionality, flexibility and quality in building site operations.

2019 saw the unveiling of the new RS26 hooklift. MEILLER set a new benchmark with this model for heavy duty operations with 3 and 4-axle vehicles.

The RS26 impressed with its lifting capacity of 26 tonnes, a weight reduction of more than 700 kg and a doubling of its operating speed. This made it the lightest, quickest and, at the same time, most powerful hooklift in its class.

MEILLER commenced operations at the new plant in Oed-Oehling in 2020. A modern production location with a hall area of 10,700 m², two painting lines and 26 cranes was created on a site covering around six hectares.

This relocation saw the closure of the previous Waidhofen an der Ybbs and Asten locations and amalgamation of production in Oed. The first tipper “made in Oed” rolled off the line on the 10 March 2020.

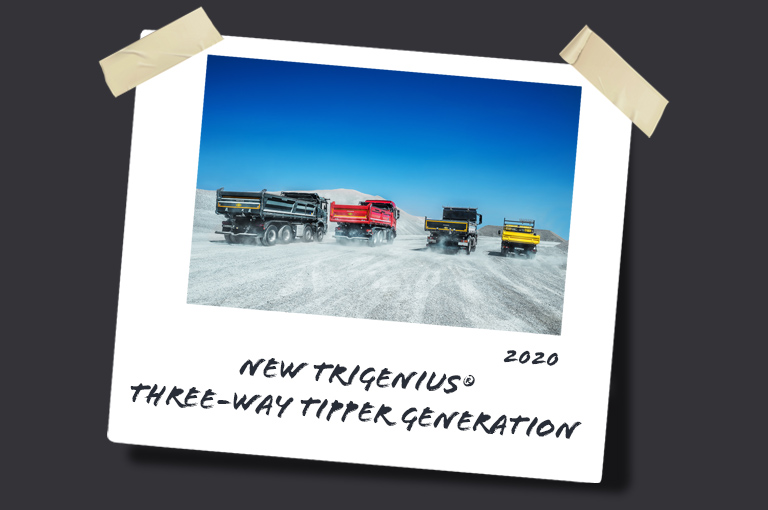

MEILLER introduced the new TRIGENIUS three-way tipper generation in 2022. The vehicles were completely redeveloped and combine the latest technology, optimised design and a high level of practicality.

The TRIGENIUS launched a new era in tipper construction – lighter, more functional and designed to meet the requirements of modern construction sites.

The launching of the new TRIGENIUS in 2022 saw the implementation of a new brand concept for the entire product portfolio, underlining its uniqueness on the market.

The tipper and superstructure variants will be marketed in future under the new GRANDLOAD, MAXTREME, TECTRIS and TECTRUM designations.

In 2025, we can thankfully look back at a long history packed with progress, innovations and success.

We are also looking forward to an equally successful future which we intend to shape together with you.