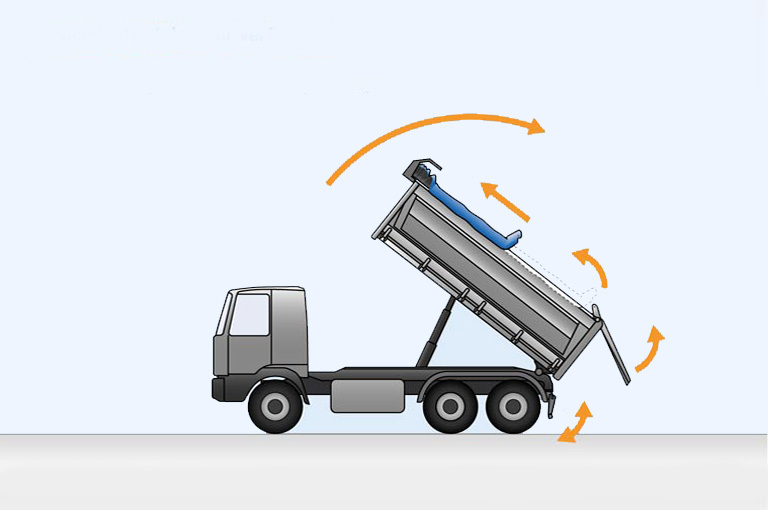

With the MEILLER i.s.a.r. radio control unit you have full command: operate from a safe distance and at a location that gives you the best visibility.

All operating functions are logical, easy to understand and intuitive to execute.

Practical: Operation is even easier with the preprogrammed sequences of the sequence control.

Profit from the quality and expertise of the market leader. With the new i.s.a.r.-control 3 operation of your tipper becomes child's play. Operate from a distance increases work safety – so no time is lost. Operating cycles and costs are thus reduced.

Control elements were reduced and the system has been supplemented with a display and a joystick. Dynamic depiction of functions on the display facilitates intuitive operation. All functions are activated with the joystick and selected by thumb using the arrow keys. Switching hands is unnecessary.

Practical operation is possible from a safe distance: with the display depicting the functions that can be realised with the respective superstructure – all in a function cycle.

Two different programme sequences are available:

Functions for the skip loader:

Operation is even easier with the preprogrammed sequences of the sequence controller, because retracting and extending the tarpaulin is integrated in the program sequence.

"Tip the tipper body" sequence control:

*Pictures similar, can include additional equipment.