With the TRIGENIUS®, MEILLER has completely redesigned the three-way tipper: inspired by users' experiences and wishes, the result is an outstanding three-way tipper that adapts perfectly to every mission.

The innovative design of the TRIGENIUS® reduces weight while the use of high-strength steel increases its loading capacity.

A uniform operating concept across all series and ergonomically designed components shorten operating cycles and make for efficient operation and handling.

All components have to undergo rigorous, harsh stress tests and have been put through their paces in operation. The result is a three-way tipper that outstandingly meets every challenge.

Economic. Reliable. Innovative:

The TRIGENIUS® is more versatile than ever before. The portfolio includes vehicles from 2- to 5-axle chassis and a nominal load of 2 to 28 tonnes. Customise your threeway tipper with a varied range of tried-and-tested accessories. The modular design and the use of bolting technology enable easy retrofitting.

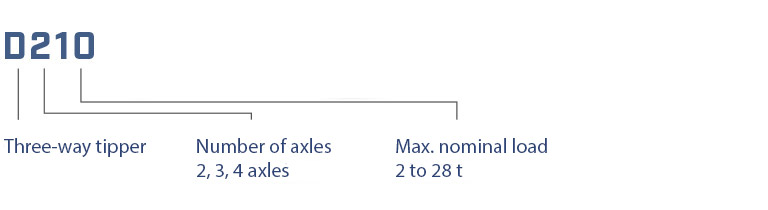

| Type | D202 | D204 | D205 | D208 | D210 | D212 |

| Nominal load | 2 t | 4 t | 5 t | 8 t | 10 t | 12 t |

| Techn. permissible gross vehicle weight | 3.5 - 4.6 t | 5 - 7.2 t | 7.49 - 8 t | 9 - 14 t | 15 - 16 t | 18 t |

| Tipper body length | 2,600 - 3,400 mm | 2,700 - 4,000 mm | 3,000 - 4,200 mm | 3,000 - 4,200 mm | 3,200 - 4,800 mm | 3,600 - 4,800 mm |

| Tipper body width | 2,000 mm | 2,000/2,200 mm | 2,000/2,350 mm | 2,200/2,350 mm | 2,380 mm | 2,450 mm |

| Side wall height | 400 mm | 400 mm | 400/500 mm | 500/600 mm | 500 mm | 600 mm |

| Floor material | 1.5 mm HBW 450 | 1.5 mm HBW 450 | 2.5 mm HBW 450 | 2.5 mm HBW 450 | 4.0 mm HBW 450 | 4.0 mm HBW 450 |

| Front wall material | 1.5 mm BS 70 | 1.5 mm BS 70 | 1.5 mm BS 70 | 1.5 mm BS 70 | 2.5 mm HBW 450 | 2.5 mm HBW 450 |

| Side wall and tailgate material | 1.5 mm BS 70 | 1.5 mm BS 70 | 1.5 mm BS 70 | 1.5 mm BS 70 | 2.5 mm HBW 450 | 2.5 mm HBW 450 |

| Type | D316 | D321 |

| Nominal load | 16 t | 21 t |

| Techn. permissible gross vehicle weight | 26 - 28 t | 33 t |

| Tipper body length | 4,400 - 5,100 mm | 4,400 - 5,100 mm |

| Tipper body width | 2,420 mm | 2,420 mm |

| Side wall height | 800 mm | 800/1000 mm |

| Floor material | 5.0 mm HBW 450 | 5.0 mm HBW 450 |

| Front wall material | 3.0 mm HBW 450 | 3.0 mm HBW 450 |

| Side wall and tailgate material | 4.0 mm HBW 450 | 4.0 mm HBW 450 |

| Type | D421 | D428 |

| Nominal load | 21 t | 28 t |

| Techn. permissible gross vehicle weight | 32 - 35 t | 41 t |

| Tipper body length | 5,400 - 6,200 mm | 5,400 - 6,200 mm |

| Tipper body width | 2,420 mm | 2,420 mm |

| Side wall height | 900/1,000 mm | 1,000 mm |

| Floor material | 6.0 mm HBW 450 | 6.0 mm HBW 450 |

| Front wall material | 3.0 mm HBW 450 | 3.0 mm HBW 450 |

| Side wall and tailgate material | 4.0 mm HBW 450 | 4.0 mm HBW 450 |

Sturdy steel tipper with low dead weight thanks to its weight-optimised design – for flexible use in the transporter class. Maximum comfort due to a low overall height and lots of space for stowing tools.

Versatile and agile three-way tipper – for virtually any terrain. Ideally suitable for transporting bulky items for construction site set-up, for municipal applications and for transporting bulk goods.

Three-way tipper with up to 2,450 mm-wide cargo area for highly universal transportation options: from bulk goods to construction site cabins. Optionally with double-plated side walls for heavy-duty use.

The robust tippers with maximum payload thanks to their weight-optimised design and high-strength steel – for maximum revenue. Particularly stable superstructure that stands out through safe operation.

![[Translate to International (English):] TRIGENIUS Three-way tipper D428 Illustration [Translate to International (English):] TRIGENIUS Three-way tipper D428 Illustration](/media/Fahrzeugbau/General/images/produkte/trigenius/trigenius-illustration-d428.png)

*Pictures similar, can include additional equipment.